Under the command of José Antonio Galizio Neto, he soon stood out in the market for producing though and high-performance watercrafts, which prioritize efficiency and low maintenance. Intech masters the open mold infusion lamination technology and is always looking for improvement and better techniques.

Intech expanded its area of operation in 2011 when it started producing four models of the famous Italian brand Sessa Marine. It currently holds the rights to represent three brands in Brazil: Sessa Marine, Key Largo and the private label Intech Professional Boats.

The experience, technology and innovative design passed on by Sessa Marine, along with the workforce and knowledge of Intech Boating in the Brazilian market, it resulted in the success achieved. Today there are already more than 300 watercrafts produced and sailing in Brazilian seas.

For us, every detail matter: building high-performance, low-maintenance boats is as relevant as design, comfort and finishes. With the new factory, we have consolidated the partnership with Sessa Marine, combining our experience and seriousness with the Italian tradition and quality in producing avant-garde boats. It was a watershed in our trajectory and also in the life of those who choose a watercraft we built.

We try to think like the user, paying attention to all the details, so that our products can be adjusted to the particularities of each client.

Today I am proud to say that we are one of the most reliable and innovative companies in the domestic nautical market. In all these years of activity, I am proud to see how we have evolved, expanded our product line, updated our champions and expanded our production capacity. Even with the family growing, we have kept our values and that is what brought us here.

We are ready for new challenges.

Welcome to the Intech family.

José Antonio Galizio Neto

With an initial investment of R$15.5 million, the industrial park was built to meet the production capacity of four boats per month of up to 50 feet, and made it possible to increase production capacity by 50%. The project was designed to allow the production of boats according to a cutting-edge industrialized production process, similar to that one carried out in the factories of its Italian partner Sessa Marine.

In 2019, a new investment of R$1.5 million, expanded the built area from 12,500 m² to an extra 4,000 m², to meet the increased market demands and the needs for the implementation of new lines of larger boats.

The industrial park holds the entire administrative and production line, with its own sectors of joinery, upholstery, locksmiths, warehouses, finishing, assembly, lamination, escape area and external patio.

Today the plant meets the production of five models from Sessa Marine, two models from the Key Largo line and the IB 360 model from Intech Professional Boats.

Such concern was also considered in the development of the new factory project. Aiming at environmental preservation and making the most of natural resources, the factory spaces were designed to enhance natural lighting with large glass panels on the ceiling and side walls, which reduce the use of artificial lighting. The factory also has a system for controlling atmospheric emissions at all stages of the production process, which prevents the dispersion of particles into the environment.

The harvesting of rainwater was another important sustainable initiative that the factory adopted. The building has a circuit system that makes it possible to collect and store rainwater for reuse in the toilets, in the watercrafts test pool and for irrigation of the gardens. The tanks can store up to 220 thousand liters of water.

Also, part of the company's routine is the selective collection of discarded materials on the production line, where all waste is previously selected in the generating sources, with a disposal without damaging the environment.

We strive for EXCLUSIVITY, our purpose is to be the best, not the greatest.

We love our production line and our products. We use all our experience to BUILD WELL and DELIVER HIGH STANDARD products.

QUALITY is our main focus, we seek continuous improvement, complying with all legal provisions.

We believe that AFTER-SALES is the main tool to keep EXCELLENCE and win our customers´ TRUST.

We are not looking for ready-made professionals, WE INVEST IN OUR TEAM. We want people who are available to develop their skills and who seek their professional and personal GROWTH. People who want to grow together. Who strive for excellence and pursue it with a daily DETERMINATION.

We talk over and solve our problems together. We are in the habit of cooperation and solidarity. Our goal is to ADD different skills, that together do something AWESOME.

WE TRUST our distribution network and keep it ready and motivated. Resellers who believe and know our products know how to improve it and how to meet our customers’ needs, ensuring a FIRST-CLASS service.

MISSION

Build high-quality watercrafts, differentiated by quality, specialization, performance and design, developing our human and technological capital, through best practices with social and environmental responsibility.

VISION

Being an internationally recognized shipyard for manufacturing the best watercrafts in its range, up to December of 2023.

VALUES

• Excellence - Keep established quality standards, always seeking improvement and specialization.

• Human capital - Respect the individuality of each employee, treating everyone with transparency and giving relevance to each person's contribution.

• Ethics – Build solid and respectful relationships with the market and partners.

• Commitment - Work with dedication and enthusiasm, focusing on customer satisfaction and building a positive image of the shipyard.

• Social and environmental responsibility - Adopt practices to preserve the environment, both in the processes on the assembly line and when using watercraft, adding to a more sustainable and conscious society.

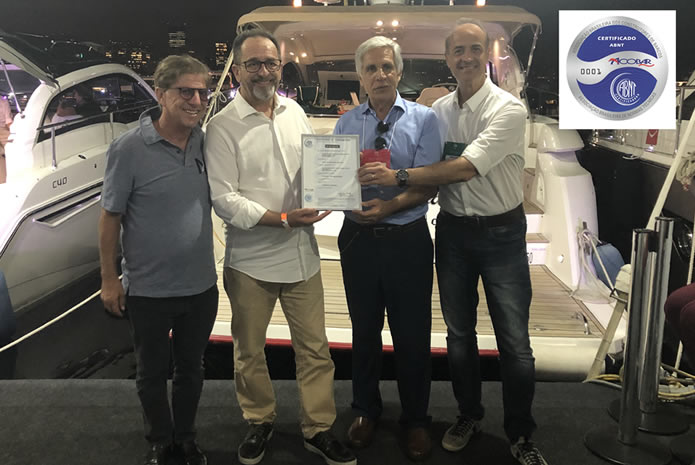

Acobar - ABNT

Intech Boating officially received the ABNT Certificate of Conformity during the Rio Boat Show 2019.

Intech Boating is the only shipyard to have its entire line certified by Acobar - ABNT.

The certification was created aiming to improving safety standards and attesting to the quality in the construction of Brazilian boats. It is directly related to the care taken during the construction, the safety of the people involved in the production process, the users of the boats, as well as the attention given to the environment.

The process includes a full checklist that must be complied with by the requesting shipyards. The certification is supported on a checklist, based on 14 international ISO Standards, national standards, in addition to the Brazilian Navy (NORMAN) standards.